Scan Process

Capture Process

Scanning Duration

Scan Data

Scan Period

LITHIC

LITHIC is the acronym for Lidar-Thermal-IMU-Camera. It Includes a 360 LiDAR, IMU sensors, RGB camera, Thermal Camera and a Multi Spectral Camera

905nm

100m

360/70° FOV

200K points/sec

2mm std

Global Shutter

Thermal Camera

Multi-Spectral Camera

2TB Storage

2.5hr Batttery

1.5 hr Data

1.7kg

Drone Scanning

Drone LITHIC

Capture Process

Geolocation

Output Process

LITHIC Drone Specifications

GPS Denied Navigation

Obstacle Avoidance

20min flight time

Mission Automation

2kg payload

80m max height

The Measurable 3D Model!

3D Mesh

2D Plan

Measurements

Accuracy

Section Planes

Volume-under-Plane

Snapping

Annotations

Google Maps

2D Floor Plan

Segmented Model

Measurements

DXF

PLY

GLTF

OBJ

RVT

IFC

Stacked Model on Google Maps

Stacking Process

Navigation

Map Layers

Side-By-Side View

3D Scan vs Camera Video

3D Scan vs BIM Model

RGB vs Thermal

Slider View

Old Scan vs New Scan

"Peel Off"

Scan History

Thermal Analytics

Processing

Moisture Seepage

Leak Profiling

Defect Analytics & Punch Lists

Snags AI

Annotated in 3D

AI Training

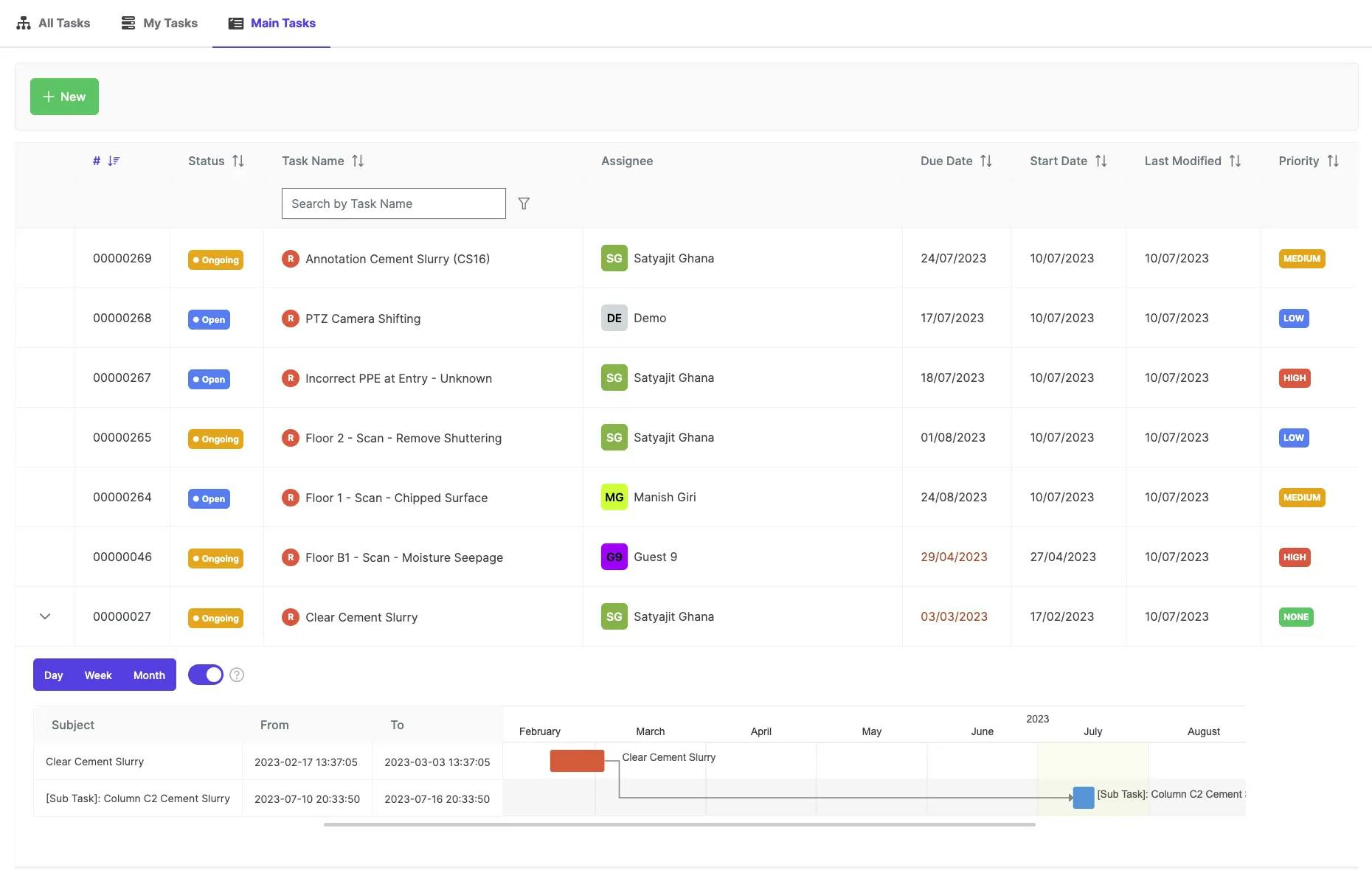

Task Manager

Annotations to Task

Task Features

Access Controls

Health&Safety Analytics

Facial Recognition

PPE Detection

AI Reports